Product Data Management (PDM) in the Electronics Industry

PDM is particularly important in the electronic components industry, where an ever-changing and constantly growing array of new technologies and products exist.

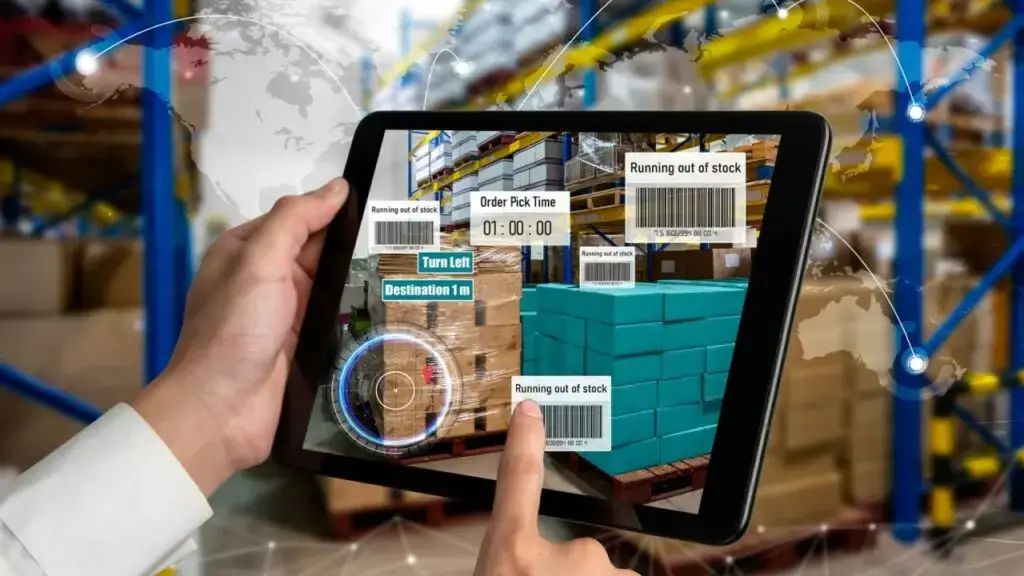

PDM streamlines manufacturing in the electronic components industry by providing visibility into production plans and inventory levels. It also helps manufacturers identify potential supply chain issues early to avoid costly delays. For example, PDM can enable accurate real-time information to identify alternative suppliers or solutions if a component becomes unavailable due to supplier issues. This helps ensure that production schedules remain on track.

In addition to streamlining production processes, PDM tools help improve sales efficiency by providing up-to-date, accurate information about available products and prices. PDM systems make it easier for sales teams to share accurate information with customers quickly and efficiently. This makes it easier for sales teams to close deals faster while providing a better customer experience overall.

Impact of Poor Product Data Management

Inaccurate and inconsistent data: This can cause problems such as incorrect pricing, outdated product descriptions, and incorrect product specifications. This leads to confusion and frustration for customers and can result in lost sales and revenue.

Reduced efficiency and productivity: For example, if product data is not accurate and up-to-date, it can take longer for teams to complete tasks, and it can be more difficult for teams to make informed decisions.

Lost opportunities: If product data is not accurate and complete, it can be difficult for the organization to be agile and responsive to take new sales opportunities.

Damage to the organization’s reputation: Poor product data management can also damage the organization’s reputation. For example, suppose customers encounter inaccurate or inconsistent product data. In that case, they may lose trust in the organization and may be less likely to do business with it.

Building Blocks of Effective Product Data Management

A single source of truth: The first step in effective PDM is establishing a single source of truth for product data. This can be a central database or data repository where all product data is stored and managed. This will ensure a consistent set of product data used across the organization.

Defined data elements and attributes: Define the specific elements and attributes that make up the relevant product data. In the electronic components industry, this can include information such as product descriptions, technical specifications, compliance certifications, pricing levels, manufacturing locations, etc.

Data quality controls: Effective and consistent controls ensure that the product data is accurate and complete. This can include processes such as data validation, data cleansing, and data enrichment. These controls can help to identify and correct any errors or inconsistencies in the product data.

Access to product data: Product data needs to be accessible to the various teams and departments that need to use it. This can be done through APIs, data feeds, and integration with other applications and systems. This will ensure that the product data is available and usable throughout the organization.

Conclusion:

Robust Product Data Management processes, systems, and tools have become vital for any company operating in the highly competitive electronic components manufacturing and sales industry. From managing efficient production processes to helping build stronger customer relationships, PDM systems offer numerous benefits that are key to staying ahead of the competition in this fast-paced industry. Investing in a good quality PDM system is a wise decision for any business looking to gain an edge in this market segment.